Hindustan Aeronautics Ltd (HAL) has once again come in the eye of the storm after a respected Test Pilot and former Indian Navy Chief did a candid interview with the web portal LiveFist and highlighted what HAL could have done better in some areas. Last year HAL was in similar situation when a public debate erupted when they came to know for the first time that the 126 aircraft Medium Multi-Role Combat Aircraft (MMRCA) Rafale contract could not go through because the foreign vendor was not willing to take responsibility for the quality control of HAL produced products and that the HAL would require 2.7 times the man-hours to produce the aircraft vis-a-vis the French manufacturer Dassault, thus a significant increase in price. Also last year the Ministry of defence (MoD) and Indian Air Force (IAF) were shocked to see that the price quoted by HAL for the Light Combat Aircraft (LCA) Mk1A was much more than what it was charging IAF for the HAL-built, much-larger and potent, SU-30 MKI. There is already very large delay in the very desperately needed LCA for IAF, and the more potent variants and increase in production are far away. We all want indigenous systems to succeed, but we also want that Indian Armed Forces get what they need to defend the nation. As a test pilot and Commandant ASTE, I had worked closely with HAL. This article is a hand holding exercise, and to help HAL introspect and get going forward.

The Indian military aviation market continues to be huge. IAF is at an all time low of 30 fighter squadrons, down from the authorized 42. If urgent steps are not taken to acquire more fighters, this number could go down further. For the IAF alone, the immediate aircraft requirements are close to US $ 100 billion worth, while the Army and Navy have their own requirements for their respective air arms. HAL should have been a flag bearer of the ‘Make-in-India’ campaign, and like ISRO should have helped India become self sufficient. It should have also helped promote the Indian private industry as part of the overall eco-system. Unfortunately it has only partially met needs of the Indian air arms, despite being in existence for nearly seven decades and having near monopoly. HAL and many other Defence Public Sector Undertakings (DPSU) continue to be highly import dependent. They have essentially managed to master the art of license-production and assemble aircraft using foreign supplied kits and production drawings. Even for making kits from raw material, they often need foreign assistance. It is time to catch this bull from the horns and give it a big shake.

HAL – Great License Production House

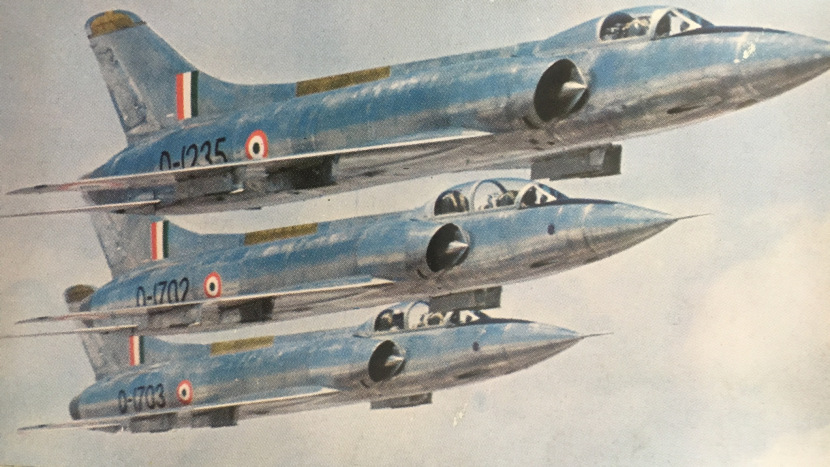

HAL began by building the Percival Prentice low-wing monoplane with a fixed undercarriage basic trainer of British design in 1950s. 89 Hawker Siddeley HS-748 medium transport aircraft were built at Kanpur. India was the largest producer of Folland Gnat and later had a more powerful Indian variant Ajeet. At one stage IAF had 8 Gnat squadrons. The aircraft did extremely well in 1965 and 1971 wars and was christened the ‘Sabre Slayer’. India began MiG-21 production early 1960s under transfer of technology. Special plants were set up at Nasik (airframe), Hyderabad (avionics) and Koraput (engine). A total of 1000 aircraft variants were produced by HAL. The upgraded MiG 21 variant Bison may go up to 2025 with depleting numbers. HAL built 165 MiG-27M. Nearly 50 of these were upgraded. Jaguars were inducted into IAF in 1979. HAL began assembly of Jaguars in 1981. Nearly 125 aircraft still fly with IAF. The aircraft have seen large number upgrades that included multi-mode radar, auto-pilot, navigation & attack system and the glass cockpit. Hawk Mk.132 joined IAF in 2008. 24 aircraft came directly from BAE Systems. 42 Hawks were initially assembled by HAL. 57 more Hawks, 40 for IAF and 17 for Indian Navy will be manufactured. Another 20 were ordered for the Surya Kiran Aerobatic team. HAL and GE Aviation signed a contract for maintenance on the Hawk fleet for next 30 years. The Sukhoi Su-30MKI air-superiority fighter specially developed by Russia’s Sukhoi for IAF requirements are being built under license. 272 aircraft, plus ten later, have been ordered. 250 are in service in 12 squadrons. All aircraft will be delivered by 2021. An upgrade for the aircraft is evolving. It will include an AESA radar, new avionics and weapons, and will also imbibe some of the technologies from the Fifth Generation Fighter Aircraft (FGFA). SU-30 MKI will be the backbone of the IAF for next two decades. In 1983 HAL got production license to build 125 Dornier Do 228 aircraft for the Asian markets. Approximately 270 were built jointly between Germany and India. In 2009, production of Dornier 228 NG(New Generation) began with fuselage in Germany, and wings and tail unit by HAL Kanpur. The first delivery was made in September 2010. IAF operates 40 Do 228-201 and 14 are on order. Indian Navy operates 26 and 18 are on order. Indian Coast Guard has 38 Do 228-101 maritime surveillance aircraft. The Aerospatiale Alouette III single-engine, light utility helicopters were built by HAL under license and named Chetak. Chetan was a variant with HAL/Turbomeca TM 333-2M2 Shakti engine. A total of 300 were built. HAL also exported Chetak helicopters Namibia and Suriname and India donated a few Chetak helicopters to Bangladesh and Nepal. The Aerospatiale SA 315B Lama was a French variant developed for hot-and-high operational requirements of Indian Armed Forces. It established a helicopter absolute altitude record of 12,442 m (40,814 ft). HAL built these as the Cheetah, and later developed an upgraded variant, powered by the Turbomeca TM 333-2M2 engine, and called it Cheetal. An armed version was marketed as the Lancer. HAL also builds Rolls-Royce Turbomeca Adour Mk 811 and Mk 871 engines for Jaguar and Hawk respectively,and Garrett TPE331-5 for Dornier and Turbomeca TM 333 engine for Dhruv.

Armed Forces Aircraft Requirements

The biggest concern for the IAF is how to rebuild and augment its highly depleted fighter force. The only current saving grace is the SU 30 MKI fleet that has significantly boosted IAF’s op potential. The indigenous Light Combat Aircraft (LCA) ‘Tejas’ which was to provide a modern jet fighter to replace IAF’s ageing MiG-21 fleets is still struggling. Only 20 aircraft have been supplied in Initial Operational Clearance (IOC), and another 20 in Final Operational Clearance (FOC) configuration, will now start getting inducted. HAL was expected to produce 18 Tejas fighters every year, and that was the only way IAF could phase out old aircraft to retain some semblance of numbers. But only 20 aircraft have been handed over in five years. LCA MK1A which will bring in a modern AESA radar, aerial refueling and easier servicing and maintainability is still at D&D stage and government has managed to resolve the excessive price quoted by HAL. LCA Mk 1A will start joining IAF not earlier than 2023. IAF has ordered 83 of these. Indian Navy (IN) had a requirement of 40 Naval LCA variants. In December 2016, they have indicated that the LCA is over weight for carrier operations and may be considered for alternate use. The LCA variant that will actually meet the IAF’s original Air Staff Qualification Requirements (ASQR) will be the LCA Mk II with the more powerful GE 414 engine. Newer variants of the same called the Medium Weight Fighter and another one called the Omni Role Combat Aircraft (ORCA), an Air Force variant of the proposed IN’s Twin Engine Deck Based Fighter (TEDBF) are being spoken of. The earliest the first flight of such a variant may take place around 2025 and actual induction around 2032. IAF proposes to buy 200 LCA Mk II. Effectively IAF will have to live a decade with LCA Mk1 variants. Rafale remains a good acquisition with state-of-the-art avionics and weapons but only 36 are contracted and they will join IAF between July 2020 and end 2022. IAF was forced to begin a fresh process for acquiring 114 more MMRCA class aircraft. Even if fast-tracked, these aircraft cannot induct before 2025. IAF fully supports DRDO’s fifth-generation stealth Advanced Medium Combat Aircraft (AMCA). This is a work still in initial progress and the aircraft may fly around 2028 and induct around 2035. India does not have a significant indigenous transport aircraft program. Also Indian armed forces await the long delayed (7 years behind) weaponisation of the Advanced Light Helicopter (ALH) ‘Rudra’ and the Light Combat Helicopter (LUH). HAL has also planned developing a Tactical Battle Support Helicopter as a tri-services project. It will be called Indian Multi Role Helicopter (IMRH). IN has issued an RFP for six medium-range maritime reconnaissance (MRMR) aircraft. IN also needs 57 Multi-Role Carrier Borne Fighters, 123 naval multi-role helicopters (NMRHs) and 111 naval utility helicopters (NUHs). Also there is a joint venture for Ka 226 T that will start one day. It can be seen that Indian armed forces have a huge military aviation market to be tapped.

HAL Has Enough Task to Deliver

HAL was founded in 1940. It is currently state owned (90 percent) with 10 percent private share holding. HAL designs and manufactures fighters, transport aircraft and helicopters and many of their major systems. It employs nearly 32,000 personnel, had assets worth Rs 5,15,523 crores (US$ 7.36 billion) in 2017, revenue of Rs 21,100 Crore ($3.0 billion) in 2019-20, and profit of Rs 2,282 Crore up 15% over the preceding year. In addition to the license production, HAL indigenously designed, developed and produced 147 HF-24 fighter jet. More recently it is producing the ADA developed LCA ‘Tejas’, and its in-house Advanced Light Helicopter (ALH) and its variants. HAL is also into overhauls and upgrades of many aircraft and engines. HAL has also obtained several multimillion-dollar contracts from leading international aerospace firms such as Airbus, Boeing and Honeywell to manufacture aircraft parts and engines. The immediate areas of concern are the need to quickly mark up LCA annual production from 8 to initially to 16 aircraft. The next set of challenges are to complete Design and Development (D&D) of already ordered 83 LCA Mk 1A. Tasks further down include developing the LCA Mk II and AMCA.

HAL Production and Quality Issues

There are essentially three issues that have slowed aircraft development and production and that has often upset IAF plans for building its force levels. HAL (and no less DRDO) have often overstated capability of having full know-how of technologies to be able to design world class aircraft. In the same breath they have overstated the timelines to deliver. As a result, most programs have been only partially successful and have seen excessive delays. LCA is decades behind schedule. The second issue is the production quality control. IAF has repeatedly pointed out production quality flaws. Russians have often questioned HAL’s production quality standards on their license produced aircraft. More recently Dassault was unwilling to take responsibility of HAL’s production quality for the Rafale. The possible reason for high man-hours for production in HAL could be inefficiency or blind-eye to overtime, thus adding to employee numbers. Analysts have suggested that it is better to have high paid experts but cut the flab and make HAL ‘lean and mean’. The third issue is the costing. HAL has offered Tejas Mark-1A at Rs 463crore ($67.5 million) a piece making it costlier than even the much bigger and operationally potent Sukhoi-30MKI which HAL themselves supply at Rs 415 crore ($60.5 million). Interestingly the Russian supplied SU-30 MKI cost Rs 330 crore ($48 million). IAF can ill-afford to pay so much more from its meager Capital budget for the possible inefficiency of HAL.

ASQR Issues – IAF Accommodating All Through

IAF is sometimes unfairly blamed for not encouraging indigenous production in their hurry to acquire state-of-the-art systems from abroad and frequently changing ASQRs. IAF’s depleted state has been reached because of unending wait for the LCA despite IAF making nearly 135 concessions because it was beyond the DRDO and HAL to be able to meet them. Jointly agreed changes are also made in those items which reach obsolescence due to delays. Since LCA Mk1 did not meet the IAF specifications, it was decided to have LCA Mk II which would hopefully meet. Since Mk II would take long to develop, the Mk 1A variant had to be evolved to fill that gap. It clearly shows that IAF has been accommodating the indigenous industry at each stage. IAF is directly responsible to the nation for defence from the air and needs state of the weapons no less in quality than the ones with its adversaries. Pointing out deficiencies does not mean that IAF has not been fully backing the LCA program. LCA continues to progress at snail’s pace despite firm orders.

CAG Report 2015

A Comptroller and Auditor General of India (CAG) report of 2015 commented that “LCA Mk-I, which achieved Initial Operational Clearance (December, 2013) had significant shortfalls (53 permanent waivers/concessions” in meeting ASR (Air Staff Requirements) as a result of which it will have reduced operational ability. Listing the shortcomings, the CAG said that the LCA Mk-I failed to meet the electronic warfare capabilities sought by IAF as the Self-Protection Jammer could not be fitted on the aircraft due to space constraints. Also, the Radar Warning Receiver/Counter Measure Dispensing System fitted on the aircraft had performance concerns. The shortcomings in the Mk-I included increased weight, reduced internal fuel capacity, non-compliance of fuel system protection, pilot protection from front, and reduced speed are expected to be overcome in the Mk-II model. The ASR deficiencies were now expected to be met in LCA Mk-II by December 2018, the Report said then. While DRDO had always showcased LCA as an indigenously-developed aircraft with indigenous content of 70 per cent, it “actually was about 35 per cent” as of January 2015. Systems such as aircraft engine, Multi-Mode Radar, Radome, Multi-Functional Display System and Flight Control System Actuators taken up for indigenous development could not be developed successfully, resulting in LCA’s continued dependence on foreign manufacturers. Talking about lack of trainer aircraft, CAG said that IAF was in the interim using an upgraded Full Mission Simulator (FMS) at ADA for pilot training, pending supply of an FMS by HAL at the LCA operating base. Long gestation period forced change of weapon systems on LCA, necessitating acquisition of new ones. It also led to design changes on the aircraft, coupled with delay in integrating R-73E missile with the radar and HDMS. Delayed identification (December, 2009) of Beyond Visual Range missiles also contributed to the delays in achieving IOC/FOC. CAG said that the manufacturing facilities at HAL cater presently to only four aircraft per annum as against the envisaged requirement of eight due to delays in procuring plant and machinery, tools and also construction of production hangars. Criticism of the Tejas was unfounded, said DRDO officials then. The Tejas has had an outstanding safety record with no accident till date. LCA Trainer is now flying.

HAL Command and Control – Cracking the Whip

Once there seemed to be an issue of coordination and ownership of the Tejas project between the HAL, IAF and Aeronautical Development Authority (ADA). IAF has had a Project Management Team in ADA since 2004. The delays in the LCA perhaps needed early whip-crack at the highest level in the government. IAF kept keeping the MoD informed in writing and kept recording delays and observations (many flight safety critical) in minutes of the meetings. But no one ever came hard on the ADA program managers who kept giving unachievable hope and deadlines. LCA Tejas is too important and its success is of national importance and critical for survival of indigenous aviation industry. Test pilots have confirmed that the aircraft flies well. Touchwood we have not lost a single aircraft till date since its first flight in 2001. LCA program will be on for next thirty odd years and it will be followed by the DRDO-HAL Advanced Medium Combat Aircraft (AMCA) so it will be a good idea for IAF to take charge of this important project now. The government has been poised to hand over the entire fixed wing and engine design and production of HAL to the IAF. An Air Marshal answerable to the Air Chief in Air HQ and through him to the Raksha Mantri is proposed to be put in charge.

IAF had significant command and control in initial years. Between 1958 to 1993, serving or retired IAF officers were Chairmen/Managing Directors. A large number of IAF officers of Wg Cdr and Gp Capt rank were General Managers (GMs) of various HAL divisions. There have been no Ex-IAF Chairmen or GMs ever since. This situation came about primarily when the government set up Aeronautical Development Agency (ADA) in 1984 to oversee the development of the nation’s LCA program. The Director General Quality Assurance (DGQA) which handles Army products has always been a senior serving Army officer. Similarly directorate of quality assurance (Naval) is headed by naval officers. The Directorate General of Aeronautical Quality Assurance (DGAQA) which handles quality assurance of aviation products has never had an IAF officer as the head. Most major Indian shipyards are headed by retired naval officers. In view of inordinate delays in LCA program and quality control issues related to HAL production, a fresh move has begun for IAF to exercise greater control over aircraft design and production. Interestingly the Pakistan Air Chief directly controls all aircraft production in Pakistan. Will such a move be allowed to succeed by the HAL unions, or bureaucracy is still a moot question.

Can an IAF Officer at the Helm Succeed?

The government proposal to hand over HAL (BC) to IAF is to minimize time and cost overruns on the LCA program, including the Mk II variant. With nearly 32,000 employees, HAL supposedly has a powerful employees union. It is contended that it will not be easy for IAF officers to control/interface with them. Historical fact is to the contrary. Those who worked closely with HAL and DRDO over the years say that the best management employee relations were when senior IAF officers were in the chair. There was respect and aura about them. They exuded great leadership qualities and human-management skills acquired in their years of service. If the naval shipyards can be run so successfully by retired naval officers, such a thing should not be an issue. Normal Indian industrial workers want to achieve for the nation and if well motivated will do no less. Such motivation can be delivered by a combat leader better. Another advantage the IAF officer will have is that he would not have been part of the local politics (likes and dislikes) that are there in many organizations in which you grow. Military officers are more likely to accept and own up organizational incapability and seek/find early solutions. An IAF officer (end user) is more likely to understand the operational deployment, flight safety implications, maintenance aspects, documentation, and significance of each system. It is often said that bureaucracy would find it easier to deal with a civilian set up because they can exercise greater control and have more flexibility, and may oppose such a move. Any HAL management must be released of bureaucratic control. An IAF officer is more likely to keep the political and IAF leadership in the know of true ground reality. There is serious opposition from within the HAL. HAL may even want such an experiment to fail if so imposed. A clear political will and signal should put this to rest.

Urgently Required Aircraft Technologies

India has been floundering in making an aircraft jet or even a piston engine. Our over ambitious go-it-alone approach has not been of help. Finally we have been forced to seek help from French firm Safran (Snecma) to recover the Kaveri engine earlier meant for LCA. HAL and DRDO have made attempts to make modern airborne radars but success has eluded and India had to fall back to Elta Israel for the interim radar for the LCA and is scouting for a partner to make the AESA radars in India. India is still long way to go for electro-optical systems and helmet mounted sights, albeit some work is already on. Similarly we need capabilities in Forward Looking Infra-Red (FLIR) and Laser designation pods. India should be able to make and export fly-by-wire and fly-by-light signaling cables and equipment. India has still to master even aircraft auto-pilots and has had to look for foreign support. In days of Artificial intelligence (AI) and Robots, this is a logical first step. AI is the future and India need to climb the band-wagon quickly. Electronic Warfare (EW) system technologies are complex and need constant evolution. India is still working to master older technologies. There is a need to work closely on EW hardware. There is very little work going on in DRDO on stealth shapes or materials. In fact we seem to have nearly given up the idea of India’s fifth-generation Advanced Multirole Combat Aircraft (AMCA) being sufficiently stealthy. The AMCA is meant to be a twin-engine, stealthy, super maneuverable all weather multirole fighter with solid-state gallium nitride AESA radar. The current first flight is already shifted to beyond 2032.

While China has become the largest producer of small unmanned aerial vehicles (UAV) in the world, for India UAV are still work in slow progress, with only DRDO’s Nishant UAV flying. UAV programs need a push. India has still to succeed in making even a commuter aircraft leave alone an IL-76 class heavy lift transport aircraft. The midsized, 80-90 seat, Indian Regional Jet (IRJ) has still to take off. Similarly the Saras small transport (20 seat) is still struggling. It is critical to succeed in a medium transport aircraft quickly. HAL has yet to deliver an indigenous basic trainer aircraft after grounding of HPT-32 over a decade ago. HAL has also not been able to succeed in the Intermediate Jet Trainer (IJT). Little is being heard about the HJT-39, CAT (Combat Air Trainer), which was to be an Advance Jet Trainer (AJT) announced in 2005. Meanwhile HAL has upgraded Hawk Mk132 designated “Hawk-I”.

HAL also has plans to develop a Medium Lift Helicopter in the 10-15 ton class. It is currently looking for foreign partners. India even needs active research in Directed Energy Weapons (DEW). India lacks weapon homing-head technologies. India has little capability in anti-radiation weapons. After success of BrahMos there is a need to become self-sufficient on some of these. Technologies are also being used to prolong life and ensure cheaper repairs. Low Life Cycle Costs (LCC) will remain crucial. India has peripheral involvement with academia in defence R&D. More serious partnership is required for innovations of core technologies. Paltry amounts are being spent on R&D. More funds are required to focus in areas of critical interest and need to be assigned to selected teams with end-state definition. With bigger Indian private players willing to invest in defence, new technologies can best be developed or imported through joint-venture route. Private sector needs some hand holding. Time for infliction has come and the future can be bright. With Make-in-India thrust more companies may set up shop in India.

Joint Venture Approach

Two major manufacturers Boeing and Airbus control bulk of the civil aircraft market; there are only 5-6 jet engine manufacturers; only three countries have reasonable access to stealth technology. The transfer of technology (ToT) contracts are most difficult to interpret and implement. There have been ToT clauses in many Indian contracts but physically nothing significant has been transferred. India has been unable to leverage its high imports on this count. No one wants to share ‘up-end’ technology even for money. With limited access to technology alternative means will have to be found. Soviet Union and China rode to aviation success by reverse engineering Western aircraft designs. Joint-ventures are the best interim option for India.

Bureaucratic Control

Defence acquisition is a complex decision-making process that needs to balance the competing requirements of expeditious procurement, development of an indigenous capability for defence sector and conformity to the highest standards of transparency, probity and public accountability. Is the ‘generalist’ bureaucracy knowledgeable or fully geared for this? Bureaucratic bottlenecks, long winding procedures and at times lack of clear political push continue to hold back both acquisitions and Make-in-India projects. Should not the bureaucrats be also accountable for delays? The Defence Ministers need to have a genuine independent feedback system to sense the ground reality. The minister chairs the Defence Acquisition Council (DAC) meetings regularly. The log-jam in this most critical Make-In-India domain has to be broken. Running more defence projects through autonomous Joint Venture route may reduce bureaucratic control. Also privatizing more DPSUs should help. The MoD has to encourage synergy between the user, the developer and the manufacturer. The Rama Rao Committee report of February 2008, recommended making DRDO a leaner and meaner R&D organization, capable of developing advanced weapon systems without huge time and cost overruns. This has still to see action.

Insider Perspective of Former Project Director LCA Flight Testing

Air Commodore K.A. Muthana, the then project director flight testing had candidly summed up in a paper published in October 2014 that the legacy of this aircrafts’ (LCA) development had been a challenge at every stage. This fine aircraft had been hostage to a series of systemic shortcomings. The program has been steered in parallel at three levels, fighter pilots (IAF), bureaucrats (MoD) and technocrats (ADA, HAL). Coordination was often lacking. The SQR were beautifully drafted and well ahead of time and based on US standards. Two design agencies ADA and HAL had its own organization specific outward facing pulls. The responsibility for, post-deployment, maintenance of documentation, software and their periodic up gradation remained vague for long. IAF is the only repository of comprehensive military aviation knowledge in the country. Its expertise was taken only in small bits. As a result, while the designers concentrated on getting the technology airborne, the design necessities of turning the aircraft into a maintainable, deployable and employable weapon platform were missed to a large extent. Excessive concentration on basic platform design and lack of attention to avionics had resulted in patch repair modules. Lack of operational expertise in design teams led to replicating Mirage cockpit logic on the aircraft without exploiting the significantly advanced hardware architecture of the Tejas. Transition from design to manufacture is a complex process that requires to be handled carefully. Correct manufacturing tolerances are important for quality of end product. Concurrent development of support systems like tools, testers and ground equipment (TTGE) was vital to deploy the aircraft quickly. Flight and maintenance simulators are important for training. There development has been unduly delayed. Yet Tejas is a wonderful flying machine. It deserved to be in squadron service years ago. Remedial action on many of the shortcomings will favorably impact the end product, Air Cmde Muthana concludes.

Insider Perspective – Former HAL Chairman

Late Wg Cdr IM Chopra, former CMD HAL had analyzed the HAL industrial picture on a much wider canvas a few years back. He wrote that HAL was no centre of excellence. Their design capability is limited but production skills are much better. Indian Space Research Organization (ISRO) and IT industry are of world standard. We can also acknowledge that missile technology has been developed reasonably well. DRDOs performance in many other programs has been not up to the mark. HAL hardly does any R&D other than development connected with a production project. HAL’s design capability is very limited. Design engineers at the middle level are good with analytical ability but the leaders are absent. The HF-24 Marut reached from design to first flight in five years, a unique achievement perhaps not even achieved in the West. This schedule became a reality because German aeronautical engineer, Dr. Kurt Tank who headed the project was an extremely good leader. LCA was a very ambitious program, and collaboration with a company in the West should have been explored. It would have greatly saved time. Composite Technology has been absorbed well as a large amount of composites have been used for fuselage structure. Advanced Light Helicopter (ALH-Dhruv) he said was a success story though there may have been slippages. The strength of HAL lies in production and overhaul. Optimistic schedules given in HAL project reports are sometimes difficult to meet. Sometimes the imported price is cheaper because of tooling cost and the high man-hours taken at HAL because of the learning. He felt it was possible to induce private sector to set up high-tech units for building accessories etc. All are interested in indigenization but there are difficulties to achieve it in high technology items. For technology developed in India, again the quantities required are too little unless export market is available. Indigenization achieved by the Indian Navy is substantial, but large numbers of items used in ships are of lower technology compared to aircraft. The growth/performance of PSUs suffers due to bureaucratic delays and interference. I think ISRO does not suffer from bureaucratic interference as Chairman is also Secretary of Department of Space reporting directly to the Prime Minister.

Revamping HAL

The LCA and AMCA fighters, mid-size transport aircraft, and medium lift helicopters are critical to succeed for India to take the next leap forward in defence production. The current bureaucratic control over DPSUs cannot succeed. HAL needs to have modern corporate structure and be made more accountable. The current promote-by-seniority senior management has to be replaced by specially selected, highly paid, corporate leaders to put at the helm. The Engineer to Technician ratio has to increase if R&D has to succeed. The socialist labor policies have to be replaced to improve productivity. DPSUs are sitting on huge land banks in prime areas which need to be hived off or utilized for core requirements. They must get out of non-core areas such as housing and transportation for the staff. HAL needs greater autonomy which will come with greater privatization.

Way Forward

HAL holds near monopoly over aircraft production in India, yet it has moved slowly over the years. Low accountability, slow decision making, inefficient labour laws and lack of modern technology have been the cause of the struggle. India remains a foreign licensed-production house and imports around 70 per cent of its military hardware. High import content makes India vulnerable to supply lines being chocked at inappropriate times. Low investment in R&D; socialistic work force with low productivity; generalist bureaucracy controlling and deciding technical activities; grown from the ranks and often fatigued PSU higher management; and lack of initiative and drive to achieve results have made DPSUs inefficient.

With Indian economy booming in the last decade, and geo-politically the West becoming more open to sharing defence technology, India sees another window to get its act together on defence production. HAL needs to cash-on the new opportunity. India is a huge defence aviation production market waiting to be tapped. It will be so much better if Indian firms can take the major share. To be a global power that is the very first step. Till then the intention is to encourage foreign companies to set up shop in India and make it their manufacturing base not only for Indian market but also for exports. Several global defence aviation majors have shown interest. US giants Lockheed Martin and Boeing are already manufacturing and outsourcing items from India. HAL has a starting edge for collaborative work.

In addition to the economic benefits, indigenization will result in increased jobs, improved capability and the development of critical technology, and ensure ready access to the best available defence equipment. India will need about 200,000 skilled people in the defence and aerospace industry in next 10 years. Large number of qualified ex-servicemen may be trained and employed. There is considerable opportunity at sub-system levels in aero structures, avionics, and actuation and control. The government wants to reduce defence imports by at least 20%-25% through domestic production. Indian industry is good at small component manufacture, electronics, software, heavy engineering, sheet metal work, high quality milling and these needs to be harnessed. Military security is one of the key attributes for any rising power. Economic strength and well-being of a nation is dependent on the secure borders and internal security. Dependence on foreign hardware has serious security implications. Latest military technologies are still the preserve of a few nations, and they do not part with these. With changing geo-political situation friends could one day change to adversaries. They could then close the tap on critical defence spares and supplies and hold the country to ransom. On the other hand procurement of important operational systems cannot be held back if HAL cannot produce it in class and time. It is thus imperative for any nation to have indigenous defence production capability. It is time that HAL is re-energized. Time to act is now lest India misses the bus again.

Picture Credit: defence.pk

1.HS 748 was produced at Kanpur and not Banglore.

2. For medium capacity passenger aircraft a mention of SARUS development by NAL/Drdo could have been appended.

3. It is quite comprehensive article. For curious readers, if the text could be subgrouped under side headings such as: Historical, Development/ Production of Fighters, Transports, Helicopters, Engines etc.

LikeLiked by 1 person

Thanks a lot for the update. Continue enjoying reading

LikeLiked by 1 person