China is reportedly developing ejectable cockpit systems for high-supersonic aircraft, with research papers and potential visual evidence of related test aircraft emerging. This technology aims to improve crew safety during high-speed flight and is linked to the development of advanced hypersonic and supersonic aircraft, potentially for both military and civilian applications. The research points to a modular escape system designed to detach from the aircraft during flight, complete with the crew.

Interestingly, only companies in USA, UK, Russia, Switzerland, France, and China make ejection seats. Martin-Baker (United Kingdom) is widely considered the industry leader; this company has produced over 70,000 ejection seats for 93 air forces worldwide and has a long history of saving lives. As of early November 2025, Martin-Baker ejection seats had saved 7,802 (recorded) lives. Martin-Baker started recording ejection data after the first documented in-flight emergency use of their seat on May 30, 1949, which was logged as “Ejectee 1“. The company updates this number as pilots successfully eject from their seats and does not publicly report unsuccessful ejections or details on aircraft lost in conflict. Due to the sensitive nature of operator deployments, Martin-Baker is not automatically made aware of ejections. They rely on official communication from operators or confirmed accident reports when they are made available.

For some time now, there has been talk in India, the fourth largest economy and the fourth most powerful military aviation power, to make its own ejection seats.

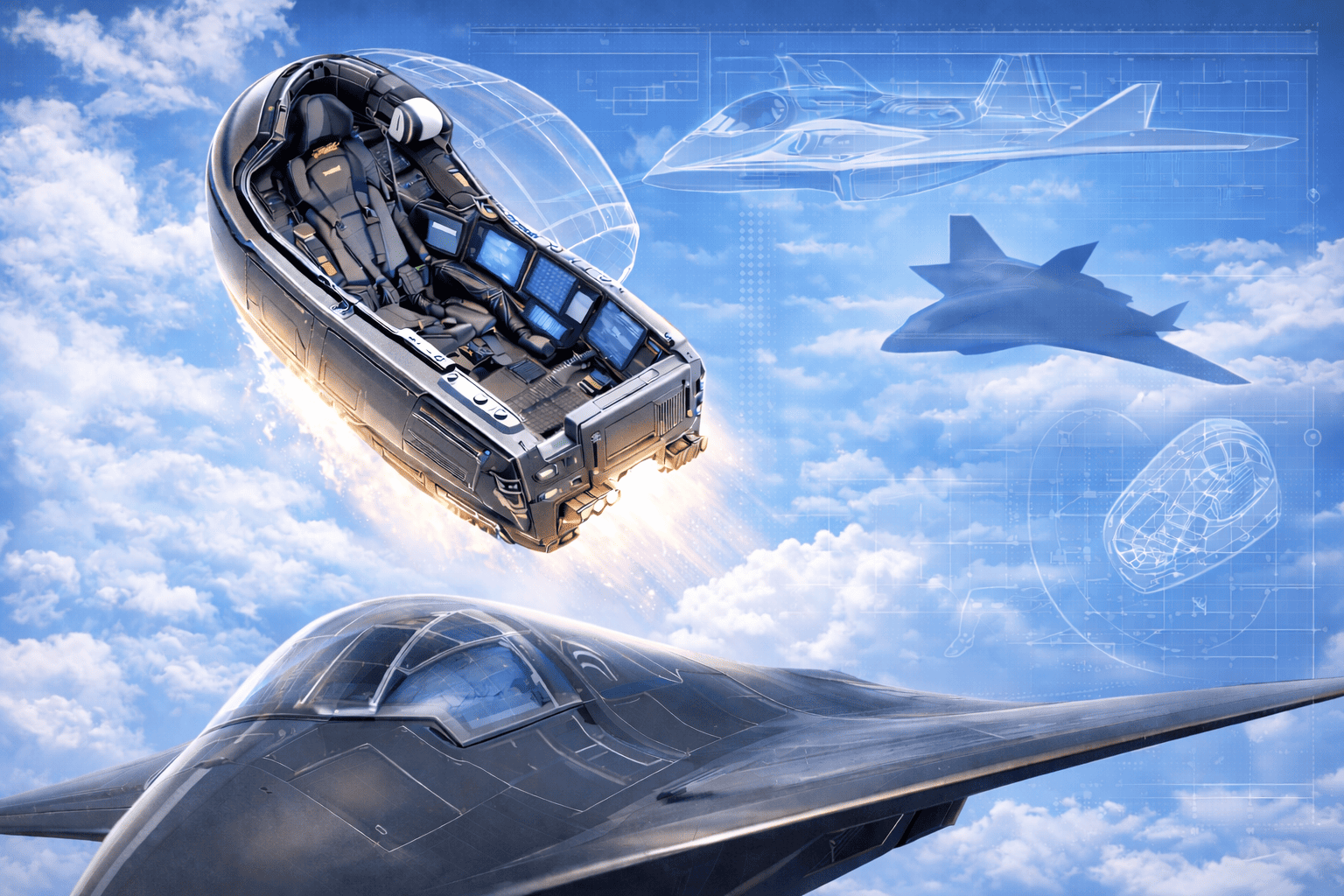

Chinese Ejectable Cockpit

A Chinese research paper on an ejectable cockpit for high-supersonic flight has drawn attention after a mysterious blended-wing test object appeared at the Gaobeidian radar range. Analysts have suggested that the research is meant to cater for crew escape from a “high supersonic aircraft” where the entire cockpit module would be ejected. The trial is reportedly being done on an unidentified flying dart-type aircraft that appeared at China’s RCS (Radar Cross Section) test site at Gaobeidian in the Hebei province first time back in October 2023. Another cranked-kite wing type aircraft was also seen at the same test site in August 2024.

The excerpts of the research paper dated 2020 were first shared by Chinese military aviation researcher Andreas Rupprecht. The paper had models, graphs, speeds and various angles of the complete module, holding an entire crew, ejecting from the top of the aircraft, supported by complex physics equations and identifying parameters like the trajectory and centre of gravity. The physical tests that started around October 2023 at the RCS facility seem to be linked to the same paper. Details of the type of aircraft used are still evolving. It is the conceptual aspect that needs more understanding.

Chinese have been publishing many dozens of aviation and dual-use technology papers, and selectively leaking them to media. Some of these are being touted as ground-breaking discoveries; many of them most theoretical in nature, may never fructify into actionable end products. Yet the quantum of research being undertaken is creditable.

China today has a significant number of flying-wing platforms. The J-36 and J-50 (J-XDS) sixth generation fighters were formally displayed at an airshow in December 2024. The aircraft have recently been spotted not at their home airfields where they were built, but at a secretive airbase with a massive runway situated near the Lop Nur nuclear test site in north Xinjiang, north-western China. The GJ-11 Sharp Sword UCAV and the CH-7 stealth drone are other examples of Chinese flying-wings. H-20 stealth bomber under development will also be a flying-wing design.

The satellite images of aircraft seen under recent tests have a compound delta-wing, like the Saab J35 “Draken”. The trailing edges extend beyond the two exhaust nozzles, giving it an overall ‘flying-dart’ like shape, similar to an early rendition of the American Next Generation Air Dominance (NGAD) fighter concept.

Notwithstanding the above, the aircraft for which the ejectable cockpit is being developed could be a large strategic bomber.

Ejectable Cockpits

China is not the first to look at “ejectable cockpits“. They were developed and used on a few specific military aircraft as escape crew capsules, where the entire cockpit or a large section of the airframe containing the crew was ejected. This was different from the standard individual ejection seats used in most military aircraft. General Dynamics F-111 Aardvark featured a system where the entire two-man cockpit module, including both seats, was ejected as a single capsule. The capsule used a parachute for descent and airbags to cushion the landing on land or water, where it could also float as a survival shelter.

Convair B-58 Hustler, Mach 2 supersonic bomber had individual encapsulated seats that enclosed the crewmember to protect them from the extreme conditions (wind blast, low pressure) of high-speed/high-altitude escape. North American XB-70 Valkyrie prototype Mach 3 bomber also used individual encapsulated seats, although testing and a fatal accident in 1966 highlighted issues with the system’s reliability.

The first three of the four Rockwell B-1A Lancer prototypes featured a single large crew escape capsule for all four crew members. For the production B-1B model, this was changed to conventional ejection seats due to cost, weight, and maintenance concerns. In the initial models of MiG 21 the canopy would fold and fix to the ejection seat during ejection, protecting the pilot from initial high speed air blast. This was discontinued in subsequent models.

Why Capsule Ejectors are Not Common?

The concept of an ejectable cockpit or crew module faced several challenges, leading to its limited use. Ejecting a large, heavy capsule requires much more powerful rockets and larger parachutes, significantly increasing the aircraft’s weight and complexity compared to individual seats. The complexity of the system introduces more potential failure points. Accidents during testing and use sometimes resulted in severe injuries or fatalities when components malfunctioned. Improvements in conventional ejection seat technology, such as “zero-zero” capability (safe ejection even at zero altitude and zero airspeed) and full pressure suits for high altitudes, made individual seats a more practical and reliable solution for most military applications. Today, the standard method for crew escape in military combat aircraft is the use of sophisticated individual ejection seats.

Why the Need for Capsule Ejection?

Ejecting while at high-altitudes and high-supersonic speeds can possibly harm the crew, and thus the idea of a secured module that protects them from the elements. As the world works towards evolving “hypersonic aircraft” for “long-range rapid deployment” and high-altitude air combat, with an expected speed of Mach 8-10, capsule ejection has once again come into lime-light. Also the world is developing “space planes” for civilian use and also military’s desire for “space control.” For long, there is a desire to have an airliner covering London to Sydney in two hours. Such planes will fly at hypersonic speeds and may be in “near space”.

Major Ejection Seat Manufacturers

Major global manufacturers of aircraft ejection seats include Martin-Baker Aircraft Company (United Kingdom), Collins Aerospace (United States), NPP Zvezda (Russia), and RUAG Group (Switzerland). Other key players also include Safran SA (France), AVIC (Aviation Industry Corporation of China), Airborne Systems (United States), and Survival Equipment Services (United Kingdom). Martin-Baker is a long-time leader in the market, supplying ejection seats to numerous air forces worldwide. Collins Aerospace is part of Raytheon Technologies Corporation. NPP Zvezda has a significant market presence globally. RUAG Group is a key player in the ejection seat market, and so are Safran SA, Airborne Systems, and Survival Equipment Services. Other important players for support and sub-systems are EDM Limited (UK), Clarks Precision Machine & Tool (USA), PacSci EMC (USA), Ensign-Bickford Aerospace & Defense (EBAD) (USA), and Chemring Group (UK), among others. Specific subsidiary companies of China’s AVIC involved in ejection seats is not clear.

Ejection Seats India

The primary manufacturer of ejection seats for Indian aircraft is Martin-Baker that is expanding its presence in India with a new facility in Bengaluru for manufacturing and maintenance. Hindustan Aeronautics Limited (HAL) is also involved, with its facilities in Nashik capable of manufacturing and overhauling seats for certain MiG variants, and the company has also sought partners to develop indigenous ejection seats. There are seat makers in the country who are looking at making ejection seats. Ejection seat is a very complex contraption. It involves great amount of sequencing of events and firing cartridges or rockets. It involves saving lives and therefore has to be absolutely fool proof safe. Modern seats allow safe ejection at zero altitude at zero speed. Also seats have to cater to very high speed ejections. But time has clearly come for some Indian companies to more actively get into seat making. Numbers involved are not very large currently. HAL and the government would have to do some hand holding. A much earlier step would be for them to make seats for India made aircraft and the various airliners bought by India. In fact on that count, the Ministry of Civil Aviation (MoCA) must come out with a positive indigenisation list (PIL) like has been done by MoD. This should include airliner seats, among many other things.

To Summarise

The future of military and civil aviation is high supersonic to hypersonic. Though sometimes it will be possible to slow the aircraft down before ejection, but there will be occasions when the ejection would have to be at high Mach No. In an airliner it would also require securing the passengers. Concepts of entire cockpit and passenger cabin detaching from the rest of the fuselage and being brought down with heavy duty parachutes and cushioning the landing with inflatables have been under consideration. Technology permits that, but there will be some penalty in terms of weight. Mathematical modelling would have to be done. Extensive wind tunnel testing will be required. The world has enough empirical data to bank on from years of research and testing of capsule ejection modules.

Meanwhile India must start the process of making own ejection seats. It will take time. We have experience of overhauling and maintaining ejection seats for decades. A joint venture (JV) route may be a good idea to begin with. Time to Act is Now.

Note: The article was originally written by the Author The Eurasian Times on November, 9th 2025, it has since been updated.

Header Picture Credit: Representative Image Generated using AI

Twitter: @AirPowerAsia