MoCA, AAI & FICCI had organized WINGS INDIA 2026, Asia’s largest event on Civil Aviation (Commercial, General and Business Aviation) at Hyderabad end January 2026. The Theme was “Indian Aviation: Paving the Future – From Design to Deployment, Manufacturing to Maintenance, Inclusivity to Innovation and Safety to Sustainability”.

India has the fastest-growing civil aviation sector, with the third-largest domestic aviation market in the world, and will become the third-largest global air passenger market in 2025. Indian aviation contributes 5 per cent of the national GDP. It also greatly promotes tourism and cargo movement. India will have 220 airports with scheduled flights in 2025, compared to 140 in 2022. In 2024, over 161.3 million domestic air passengers travelled in India, up 6.12 per cent from the year before. The current airliner fleet of around 750 aircraft will more than double in five years. Airlines engaged in domestic air travel are IndiGo, Air India, Akasa Air, and SpiceJet. IndiGo holds nearly 61 percent share of the domestic air passenger market. Airlines are increasing their capacity deployment to accommodate the growing demand for domestic air travel. 100 percent FDI is cleared in most sectors of civil aviation. The two largest Indian airlines, IndiGo and Air India, have announced plans to acquire over 500 aircraft each in the coming decade.

Boeing has delivered over 20,000 jetliners since the 1950s era of the B-707. Airbus, a European multinational aerospace corporation founded in 1970, has built more than 13,500 commercial aircraft. China’s home-grown single-aisle COMAC C919 is already flying. The still under-development and unseen wide-body, 280-seat C929 jet has already announced buyers. India still has a long way to go before it has its own home-grown airliner. India is also heavily dependent on global markets for maintenance, repair, and overhaul (MRO) of its civil aviation fleets.

Global Predictions

The total worldwide commercial aircraft fleet size is over 28,000 aircraft. In its 2023 report, Airbus’ Global Market Forecast (GMF) 2023–2042 predicts demand for passenger traffic will grow annually by 3.6% CAGR over the next 20 years. Airbus forecasts a demand for 40,850 new passenger and freighter aircraft deliveries over the next 20 years, of which 32,630 will be single-aisle and 8,220 wide-body. Another report from Oliver Wyman anticipates growth to over 35,000 aircraft within the next decade. A June 2023 Boeing forecast has predicted somewhat similar numbers.

Transport Aircraft Production Ecosystem in India

Hindustan Aeronautics Ltd (HAL) has been making the HS-748 ‘Avro’ and Dornier D-228 aircraft in India under licensed production. Both have also been used for civil aviation. Also, National Aeronautics Laboratory (NAL) has designed and test-flown the ‘Saras’ small transport aircraft. This work is still in slow progress. The Tata Group companies are already building aero-structures for many helicopters and also C-130J transport aircraft for global customers. They are also working with GE to manufacture CFM International LEAP engine components in India. Many Indian MSMEs and start-ups are in aircraft systems production.

Meanwhile, a Tata consortium is building 40 EADS CASA C-295 MW aircraft and significant numbers of its sub-systems in India at a plant in Baroda, Gujarat. The first Made-in-India aircraft will roll out of the new facility in September 2026. Before deliveries are completed in 2031, a D-level MRO facility will be set up in India. This facility will act as a regional MRO hub for various variants of C-295. The indigenous content will be the highest ever in India, with 96 percent of the work that Airbus does in Spain gradually being done in India. There are more than 125 domestic MSME suppliers spread across different states. This project should also help India in pushing its commuter aircraft.

Global Regional Jet Players

While Boeing and Airbus have dominated the large commercial aircraft market, there are other players in the regional jet market, like Bombardier of Canada and Embraer of Brazil. There are other players in the business aircraft market such as Beechcraft, Cessna, Dassault, Gulfstream, etc. Around 200 regional jets are built by various manufacturers every year. China’s C909 is a 78–90-seat regional jet. The HAL/NAL Indian Regional Jet (IRJ) is planned to be a 90-seater with a targeted first flight around 2026.

The Next Logical Step – Indian Airliner

The next logical step for India would be to build its own short-haul ATR 42 and ATR 72 class aircraft, and later also single-aisle aircraft of Boeing 737 and Airbus A320 class. Initially, ATR, Airbus, or Boeing should be asked to set a production line in India.

To collaborate on opportunities in aircraft manufacturing, supply chain, aftermarket services and pilot training, global aerospace leader Embraer and Adani Defence & Aerospace on Tuesday signed a memorandum of understanding (MoU) to develop an integrated regional transport aircraft ecosystem in India. The potential partnership will leverage Embraer’s deep engineering and aircraft manufacturing expertise alongside Adani’s aviation value-chain footprint.

Hindustan Aeronautics Limited (HAL) and Russia’s United Aircraft Corporation (UAC) signed an MoU on October 27, 2025, in Moscow to manufacture SJ-100 regional passenger jets in India. This partnership aims to produce the 103-seater twin-engine aircraft for domestic, short-haul routes under the UDAN scheme, marking a major step towards strengthening local, indigenous, civil aerospace manufacturing. The SJ-100 was showcased at Wings India 2026. HAL’s presence at Wings India 2026 goes beyond symbolism. The company will showcase a full civil portfolio spanning regional fixed-wing aircraft, helicopters and future-ready platforms, anchored by the SJ-100, the H-228 commuter aircraft and the Dhruv New Generation helicopter.

Similarly, India must also get some major civil airliner aero-engine manufacturer to set up a production line in India with a local partner. The GE-414 fighter aero-engine will be made in India by General Electric in a joint venture with Hindustan Aeronautics Ltd (HAL), with some level of technology transfer. These will be used for the Light Combat Aircraft (LCA) and Advanced Medium Combat Aircraft (AMCA). For civil aero-engines, we must insist on a joint venture with significant technology transfer by leveraging high numbers and a growing market.

Huge MRO Market

India has a huge MRO market for civil and military aircraft and engines. A 2023 CRISIL report states that India’s MRO sector still faces obstacles such as difficulty obtaining credit, inadequate infrastructure, high taxes, licensing and certification issues, and high rental costs. But the Indian government has introduced several policies to support making the country a global MRO hub. These include reducing GST on MRO services from 18% to 5%, land lease policies for longer durations to lower rental costs, and discontinuing the 13% government-charged royalty on revenue. These should reduce costs by 10–20 percent.

Setting up an MRO is highly capital intensive, with a long break-even time. It requires continuously reskilled manpower and repeat investments in tooling, and certification from safety regulators such as the DGCA, FAA, and EASA, and global OEMs such as Airbus, Boeing, and many others.

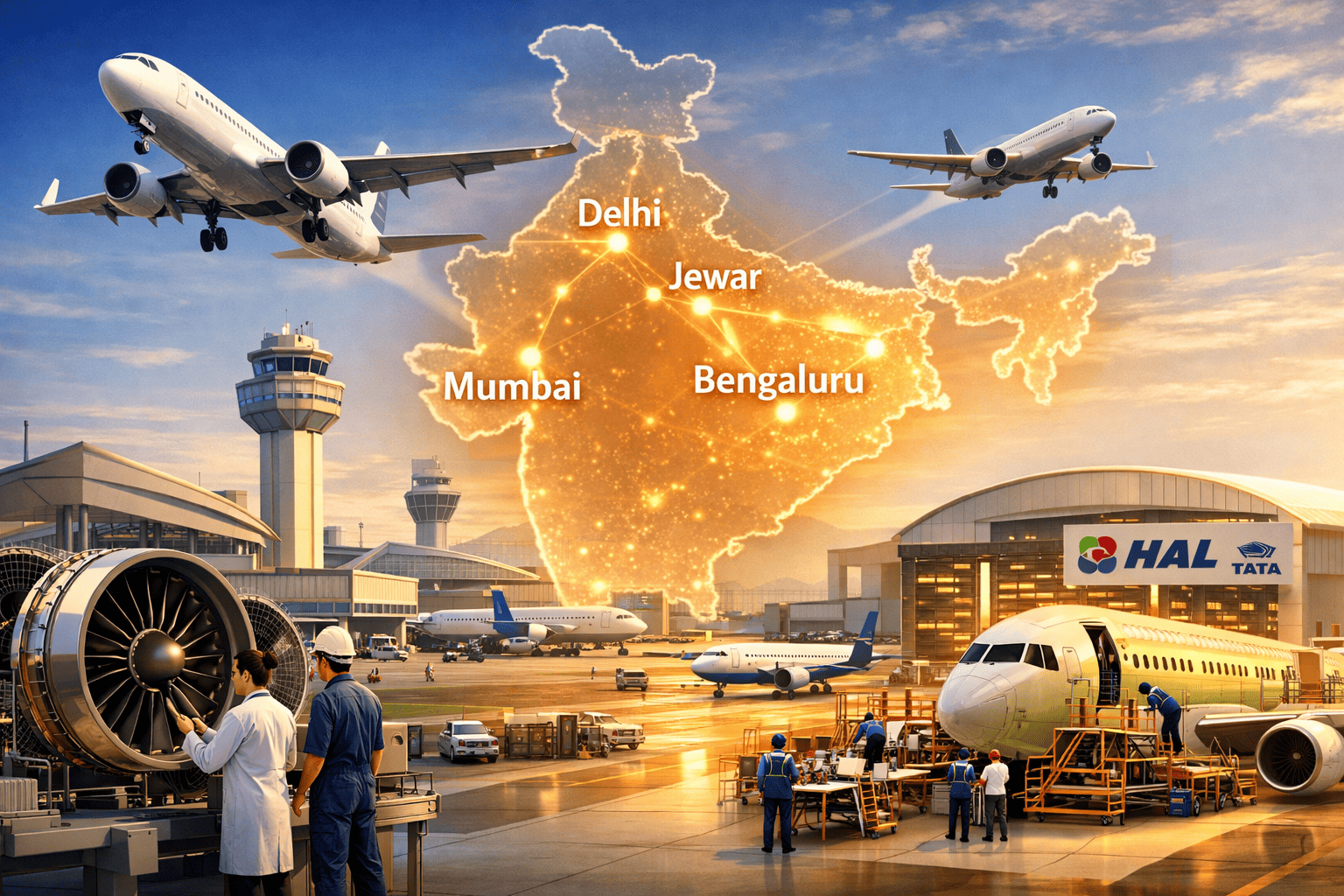

Meanwhile, the Delhi and Bengaluru airports have dedicated MRO facilities which are being expanded. A huge MRO hub will come up at the Noida International Airport, Jewar, Uttar Pradesh. More airports like Belagavi, Bhopal, and Tirupati will have MRO facilities. India’s Directorate General of Civil Aviation (DGCA) would have to stipulate international standards on the lines of those by FAA and EASA for international recognition.

The Indian government’s top think-tank, NITI Aayog, has recommended an incremental approach, by first setting up joint ventures in India with global players, and gradually ascending the work-value chain. Ultimately, India must aspire to be an international-class MRO hub like Singapore. A surge in local MRO facilities will be good for airline operations, safety, and costs.

The Indian MRO industry was $1.7 billion in 2021. The global MRO market was worth US$78.6 billion in 2022. The Indian market is expected to be $4.0 billion by 2031, growing at 8.9% CAGR, faster than any other country. India thus has great potential to be a significant regional MRO hub and gradually strive to establish its foothold in the global supply chain.

Current MRO Players

The current major Indian MRO players are AIESL (Air India Engineering Services Ltd), Air Works India, and GMR Aero Technic Limited, among a few others. HAL and Airbus have formalized an agreement to establish state-of-the-art MRO facilities for the A320 family of aircraft. The airline’s growth makes a great case for strategic investors, OEMs, and global MRO players. Policy initiatives such as the MRO Policy 2021, National Civil Aviation Policy 2016, and rationalization of GST are great incentives.

Challenges and Opportunities

100 percent FDI is already cleared in most sectors of civil aviation, but India has not yet leveraged large airliner orders. The country does have manufacturing and assembly skills but lacks original design work. The narrow-body airliner market is huge. India must insist Boeing and Airbus set up assembly lines in India and give component orders to local manufacturers. Large groups like Tata with aero-structure manufacturing experience, and simultaneously operating a huge airline, can bag more manufacturing orders. In the civil aviation sector, HAL is already manufacturing aircraft parts for Boeing and Airbus, manufacturing Dornier 228 for RUAG of Switzerland. But it is a minuscule part.

India must set up an independent authority on the lines of the Aeronautical Development Agency (ADA) to push civil aviation aircraft development. It must function under the PMO as it would involve inter-ministerial support. It may subsume the transport aircraft building facilities of HAL and NAL.

The agency can also be tasked to work on the MTA for IAF. The agency must also drive building MRO facilities. We may seek foreign consultancy for aircraft design. India must insist on foreign OEMs to set up engine manufacturing through a joint-venture route. Why cannot India make aircraft seats and other interiors in India itself? Aircraft avionics is another area where India is way behind.

The West is moving out of China. Europe has a high cost of production. India is the next best destination. India also has large land banks near airports, especially the newer greenfield ones. Government policies are becoming more attractive for promoting manufacture and shifting MRO to India. Finally, India has to invest much more in R&D. Developing your own designs and having your own patents is important. India is a rising star. The time to act is now, lest we lose another golden opportunity. It has to be a whole-of-nation approach.

The Way Ahead

The indigenisation push in the MoD in the last few years has been very significant, and the results are already visible. In the last two months, a similar push has been initiated by the Ministry of Civil Aviation (MoCA). Very recently, two of our major airlines, IndiGo and Air India, placed orders for nearly 1,000 airliners. But as a nation, India did not make sufficient efforts to derive indigenisation benefits. India has clearly been less aggressive on this count. The National Civil Aviation Policy (NCAP) 2016, and later variants, aim to create an integrated ecosystem for the growth of the Indian civil aviation sector, making flying more affordable and accessible, while also enhancing safety, security, and sustainability. It focuses on regional connectivity, ease of doing business, and promoting tourism and employment. There is no mention of indigenisation.

An order for 1,000 airliners means nearly 8,000 aero-engines in their lifetime. If the purchase had been suitably coordinated, we could have insisted that the aero-engines be made in India. Significant sub-systems could then have been sourced from India. On average, each airliner requires nearly 200 passenger seats. For 1,000 aircraft, it would have meant 200,000 seats. If India were to insist on Boeing or Airbus that the seats must be made in India, then they would develop local vendors and support them in quality global-standard manufacture, and EASA, FAA, and DGCA certification.

We have seen vendors at Aero India and the Defence Expo who are already exporting a variety of civil airliner components and sub-parts globally. There is a huge vendor base being created by C-295 manufacture in India.

Why aircraft seats, interiors, carpets, curtains, and galley equipment cannot be made in India? Why should they be imported by the fourth-largest economy of the world that also has the fourth-best manufacturing base in the world? DGCA has recently approved seats of one company. Surely, a pool of vendors can be created and encouraged. India must concentrate on low-hanging fruit first. Like MoD, MoCA must come out with a Positive Indigenisation List (PIL). The list can also define realistic timelines.

The Indian MRO market is experiencing significant growth and is poised to become a major player in the global aviation industry. Currently estimated at $2.6 billion, it is projected to reach $4 billion by 2030, growing at 8.9% CAGR, faster than any other country. The global aircraft MRO market size was estimated at $90.85 billion in 2024 and is projected to reach $120.96 billion by 2030. India thus has great potential to be a significant regional MRO hub and gradually strive to establish its foothold in the global supply chain. HAL and Airbus have formalized an agreement to establish state-of-the-art MRO facilities for the A320 family of aircraft.

Lastly, India must push its own regional jet and single-aisle aircraft. The soon-to-be third-largest economy cannot be an airliner importer forever.

Note: The article was originally written by the Author for Indian Aerospace Defence Bulletin on 12th, September 2025, it has since been updated.

Header Picture Credit: Representative Image Generated using AI

Twitter: @AirPowerAsia